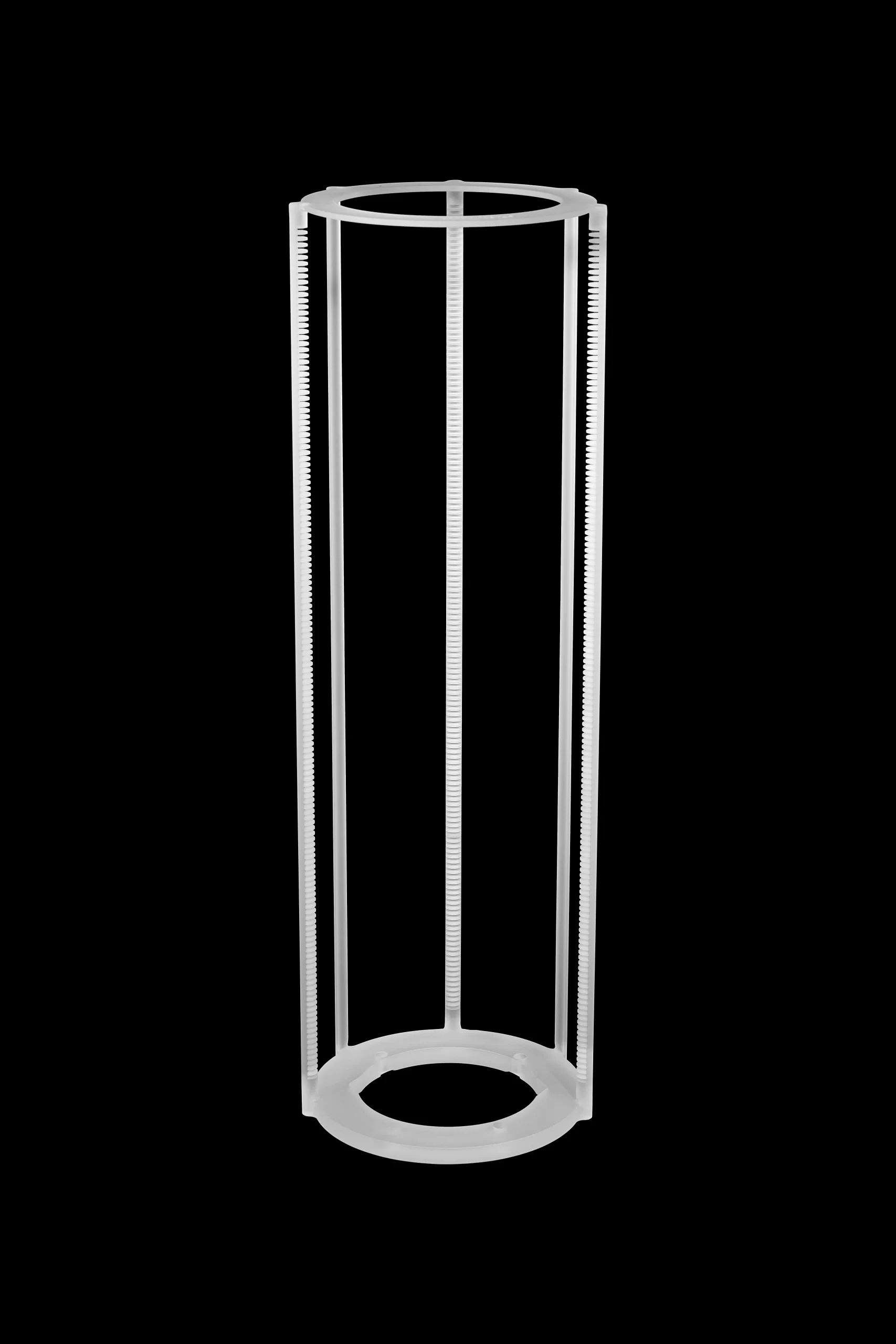

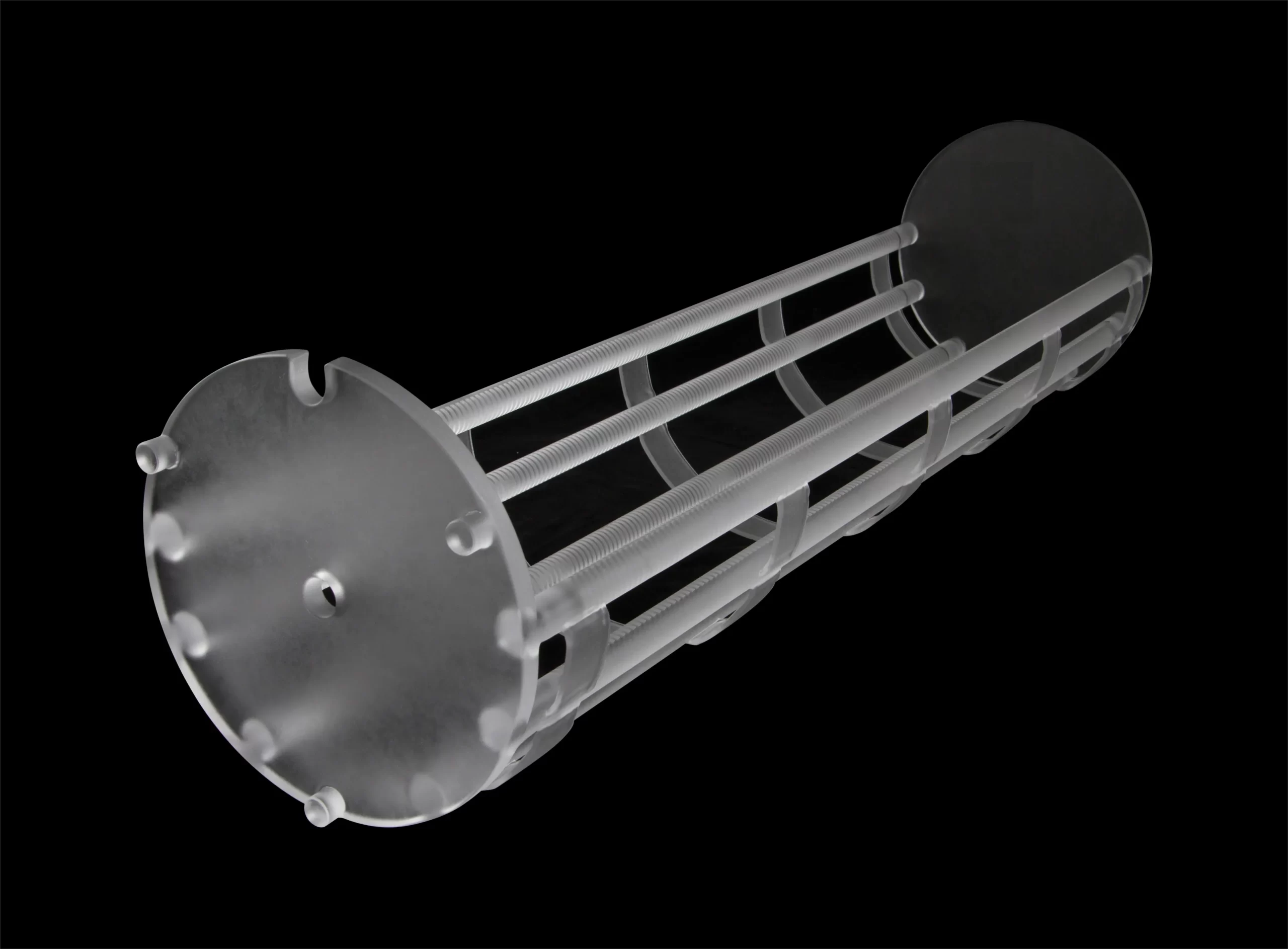

Quartz Glass Wafer Carriers – Precision Handling for High-Purity Processes

Our Quartz Glass Wafer Carriers are designed to provide safe, stable, and contamination-free support for silicon wafers during semiconductor and research processing. Crafted from high-purity quartz glass, these carriers offer outstanding thermal and chemical resistance, making them ideal for critical applications in wafer fabrication, diffusion furnaces, LPCVD, oxidation, and annealing.

Premium Material – High-Purity Quartz Glass

Manufactured from fused quartz (SiO₂) with purity levels exceeding 99.99%, our wafer carriers are built for performance in ultra-clean, high-temperature environments. Quartz glass is known for its:

-

Excellent Thermal Stability: Withstands temperatures over 1000°C with minimal expansion.

-

Low Thermal Expansion: Reduces risk of cracking or warping under thermal cycling.

-

Chemical Inertness: Resistant to most acids and reactive gases commonly used in semiconductor processes.

-

High Cleanliness: Non-porous and easy to clean, ensuring reduced particle contamination.

These properties make quartz glass the preferred material for maintaining wafer integrity in advanced microfabrication and R&D environments.

Standard Sizes for Industry Compatibility

To support a wide range of applications, we offer quartz glass wafer carriers in the most commonly used sizes:

-

3 inch (76.2 mm)

-

4 inch (100 mm)

-

8 inch (200 mm)

Each carrier is precisely engineered to ensure a secure fit for wafers of the corresponding diameter, minimizing movement during thermal or transport processes. Custom slot spacing, wafer count, and configurations are available upon request to match specific equipment and process needs.

Applications Across Industries

Our quartz wafer carriers are widely used in:

-

Semiconductor Fabrication

-

Photovoltaic (Solar Cell) Manufacturing

-

MEMS and Microelectronics R&D

-

Laboratory-Scale Thermal Processing

-

Wafer Cleaning, Transport, and Storage

Whether you’re operating a high-volume fab or conducting small-batch experimentation, these carriers provide consistent support and protection for your wafers at every stage.

Key Features

-

Smooth, Polished Surfaces to prevent wafer scratches and particle shedding

-

Precision-Machined Slots for accurate wafer alignment and stability

-

Strong, Rigid Design to maintain structural integrity at high temperatures

-

Cleanroom Compatibility with ISO-class manufacturing and packaging

Why Choose Our Quartz Glass Wafer Carriers?

-

Superior Material Quality – High-purity quartz ensures safe, clean processing

-

Consistent Manufacturing Standards – Strict quality control and dimensional accuracy

-

Customization Options – Tailored designs for your specific wafer handling needs

-

Experienced Support – Our team can help you choose the right carrier for your process

评价

目前还没有评价