Due to its excellent optical clarity and low thermal expansion, quartz glassware is used in quartz lenses, prisms, quartz plates, quartz discs, quartz wafer carrier, and other optical instruments. Its ability to transmit UV light and resist extreme conditions makes it essential in both scientific and industrial optical systems.

Reliable Quartz Glass Products Manufacturer

Our company, based in Lianyungang, China, is a leading manufacturer and supplier of premium fused quartz products. With 20 years of experience, we specialize in producing quartz tubes, plates, crucibles, and custom quartz instruments. Our dedication to precision and quality ensures that each product meets the highest industry standards.

Utilizing advanced technology and a highly skilled team, we are committed to delivering innovative and reliable solutions for a wide range of industries. Whether you require standard or fully customized quartz glass products, we are here to provide exceptional service and top-tier craftsmanship tailored to your specific needs.

Hot-Sale Fused Quartz Glass Items

Types of Fused Quartz Glass Products We Made

Quartz Glass Boat

Our quartz glass boats are highly durable and thermally stable, ideal for precision industrial processes.

Get a free quote

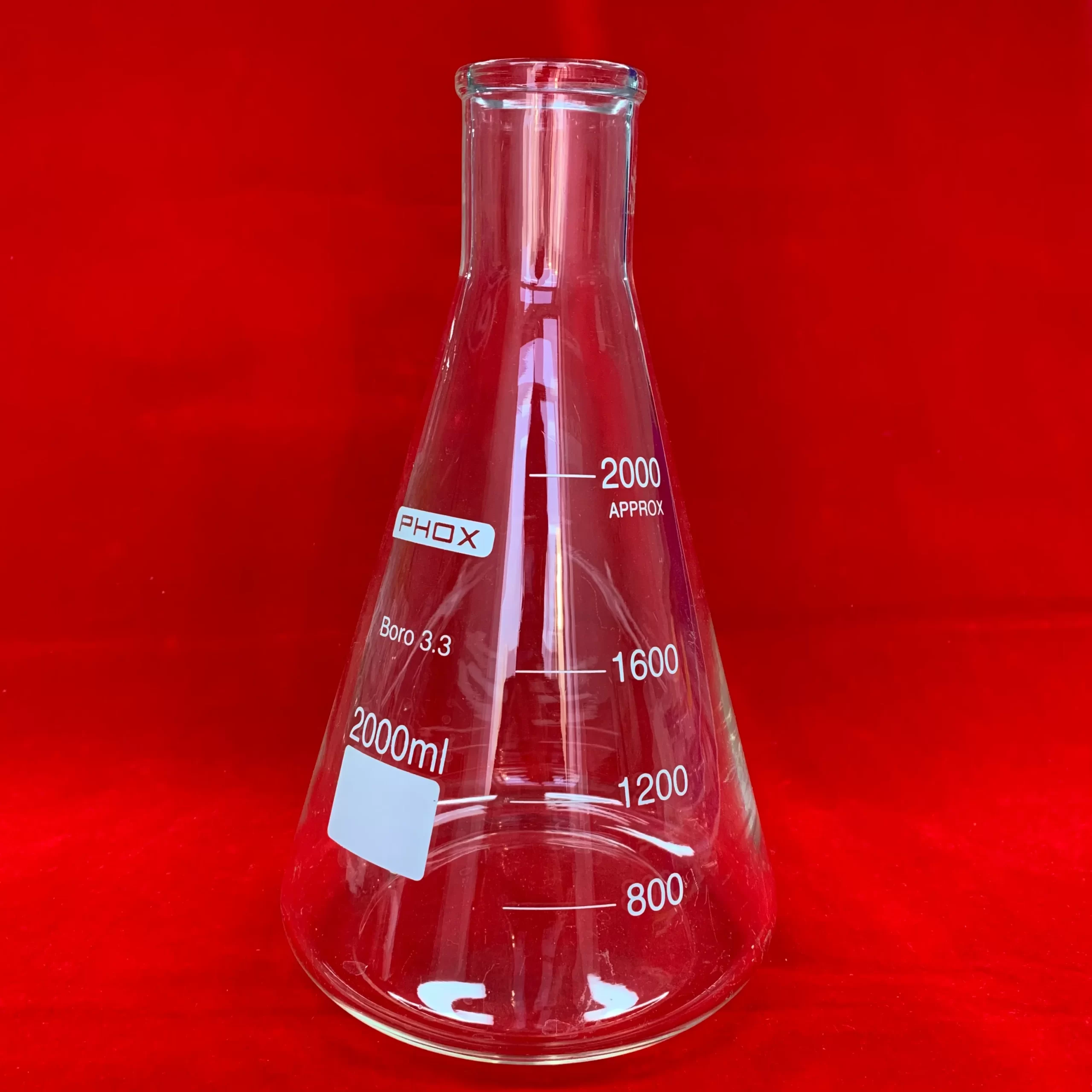

Lab Quartz Glassware

Our lab quartzware is designed for high-purity, heat-resistant, and reliable performance in scientific applications.

Get a free quote

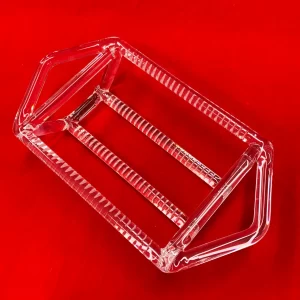

Quartz Wafer Carrier

Our quartz wafer carriers provide exceptional thermal stability and purity for secure handling in semiconductor manufacturing.

Get a free quoteOpaque Quartz Plate

Our opaque quartz plates offer excellent thermal insulation and high durability for specialized industrial applications.

Get a free quote

Frosty Quartz Glass Sheet

Our frosty quartz glass sheets feature a translucent surface with high thermal resistance, perfect for diffusing light and heat in demanding applications.

Get a free quote

Milky White Fused Quartz Glass Disc

Our milky white fused quartz glass discs provide excellent thermal stability and diffusion properties for high-performance applications.

Get a free quoteSquare Clear Glass Plates

Our square clear glass plates offer high transparency and precision, ideal for optical and industrial applications.

Get a free quoteHeavy Wall Transparent Quartz Glass Sheet

Our heavy wall transparent quartz glass sheets deliver superior strength, clarity, and thermal resistance for demanding industrial uses.

Get a free quoteRound Fused Quartz Glass Disc With Holes

Our round fused quartz glass discs with holes offer precision machining, high purity, and excellent thermal stability for specialized applications.

Get a free quoteGraduated Quartz Glass Cylinder

Our graduated quartz glass cylinders provide high clarity, heat resistance, and precise measurement for laboratory applications.

Get a free quote

Round Bottom Quartz Glass Beaker

Our round bottom quartz glass beakers offer excellent thermal resistance and clarity, ideal for reliable laboratory use.

Get a free quote

Three Mouths Quartz Flask

Our three-mouth quartz flasks are designed for versatile lab use, featuring high durability and heat resistance.

Get a free quoteThree Legs Quartz Glass Crucible

Our three-legged quartz glass crucibles provide stability and superior heat resistance for precise high-temperature applications.

Get a free quote

Silica Crucible With Lid

Our silica crucibles with lids offer enhanced containment and heat resistance for precise high-temperature processes.

Get a free quoteTransparent Quartz Glass Crucibles With Ring Lid

Our transparent quartz glass crucibles with ring lids ensure secure containment and high visibility for accurate high-temperature experiments.

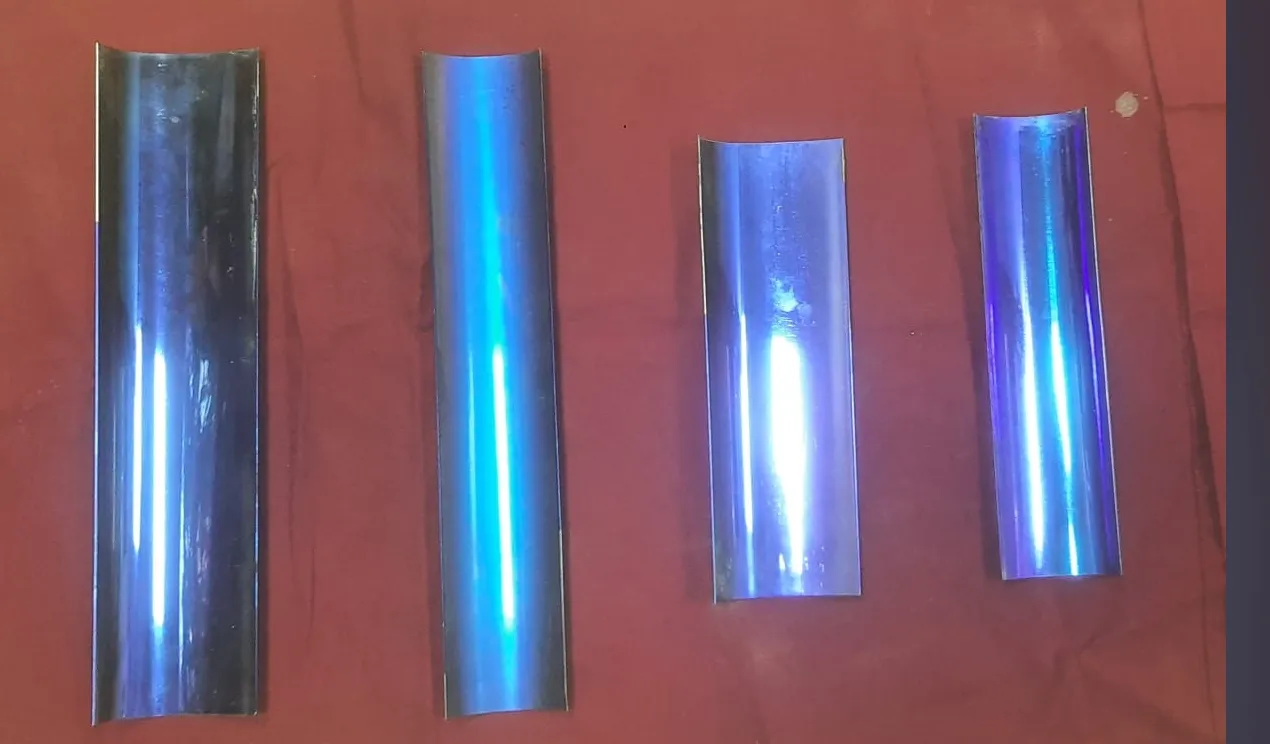

Get a free quoteFused Quartz Glass Tube

Our fused quartz glass tubes offer exceptional purity, strength, and thermal stability for a wide range of industrial heating applications.

Get a free quote

Custom Quartz Tubing

Our custom quartz tubing is tailored for precise specifications, providing superior clarity, durability, and thermal performance.

Get a free quote

UV Quartz Glass Tube Pipe

Our UV quartz glass tube pipes deliver high transmission and durability for effective UV light applications.

Get a free quoteCone Quartz Glass Sleeve

Our cone quartz glass sleeves provide exceptional heat resistance and durability for specialized industrial processes.

Get a free quote

Bell Mouth Quartz Glass Pipeline

Our bell mouth quartz glass pipelines offer smooth, high-purity flow for efficient and reliable industrial operations.

Get a free quoteWater Treatment Fused Quartz Glass Tubing

Our water treatment fused quartz glass tubing provides superior purity and durability for efficient and reliable filtration processes.

Get a free quote

Fused Silica Tubing With Screw Ends

Our fused silica tubing with screw ends ensures secure connections and high thermal resistance for demanding applications.

Get a free quoteMuffle Furnace Quartz Coil Tube

Our muffle furnace quartz coil tubes offer excellent thermal stability and durability for high-temperature furnace applications.

Get a free quoteMilky White Quartz Glass Crucible

Our milky white quartz glass crucibles provide high thermal resistance and purity for precise high-temperature processing.

Get a free quote

Round Fused Silica Crucible

Our round fused silica crucibles provide exceptional heat resistance and purity for precise high-temperature processes.

Get a free quoteGet Your Custom Quartz Glass Products

Our company offers extensive customization options for fused quartz glass products, such as fused quartz glass tubings, fused quartz glass discs, quartz crucibles, quartz boats, and quartz glassware. They are designed to meet the specific needs of various industries. We work closely with clients to ensure that every aspect of their product, from material selection to design, meets their exact specifications.

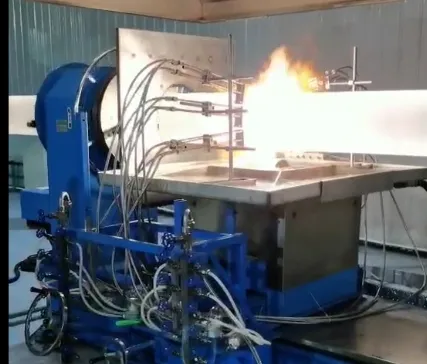

Quartz Glass Tube Manufacturing Process

Raw Material Selection: The process begins with selecting high-purity quartz sand.

Melting Process: The quartz sand is heated in specialized furnaces at temperatures exceeding 2000°C, transforming the sand into a molten state.

Tube Formation: The molten quartz is shaped into tubes through a specialized process, typically using a rotational forming or drawing method.

Annealing: After the tubes are formed, they undergo an annealing process where they are gradually cooled in controlled conditions.

Cutting and Sizing: Once annealed, the quartz tubes are cut to the specific lengths required by the customer.

Surface Treatment: Depending on the application, the surface of the tubes may undergo additional treatments, such as polishing or etching.

Quality Control: Each quartz tube undergoes a thorough inspection to ensure it meets the required specifications.

Customization: Clients can request custom dimensions, wall thicknesses, and tube diameters to meet the needs of specific applications.

Final Packaging: After quality checks, the quartz tubes are carefully packaged to prevent contamination and damage during shipping.

GET A FREE QUOTE

Quartz Rod Design Details

-

Raw Material Sourcing: High-purity quartz sand is the primary material used in the production of quartz glass rods.

-

Melting Process: The quartz sand is melted in high-temperature furnaces exceeding 2000°C.

-

Rod Formation: The molten quartz is shaped into rods using precision molds or drawing techniques.

-

Annealing: After forming, the quartz rods are subjected to an annealing process.

-

Cutting and Sizing: Once annealed, the quartz rods are cut to the desired lengths based on customer specifications.

-

Surface Treatment: Depending on the application, quartz rods may undergo surface polishing or treatment.

-

Quality Control: Each quartz rod is inspected for dimensional accuracy, surface quality, and purity.

-

Custom Specifications: Clients can request specific customization options.

-

Final Packaging: After quality checks, the quartz rods are carefully packaged to prevent damage during transit.

Quartz Plate Manufacturing Process

Raw Material Selection: The manufacturing process begins with selecting high-purity quartz glass sand.

Melting Process: The quartz sand is subjected to extremely high temperatures in a specialized furnace.

Shaping and Forming: the molten quartz is shaped into optical windows using molds or custom tooling

Annealing: After shaping, the quartz glass is slowly cooled in an annealing furnace.

Surface Polishing: The next step involves polishing the surfaces of the optical window to achieve the desired optical clarity.

Coating Application (Optional): Depending on the application, an anti-reflective or protective coating may be applied to the surface of the optical window.

Quality Inspection: Each optical window undergoes a thorough inspection process.

Final Packaging: Once inspected, the optical windows are carefully cleaned and packaged in a way that prevents any damage during transportation.

Quartz Glassware Application

Paper boxes, also known as cartons, are versatile packaging solutions that are used in a wide range of industries. They are made from paperboard, a type of thick paper that can be easily printed on, cut, and folded to create custom packaging solutions. In this article, we will explore some of the many applications of paper boxes.

Quartz glassware for Laboratory Equipment / Lab Quartz Glassware

Quartz glassware is widely used in scientific laboratories for experiments that involve high temperatures, corrosive chemicals, or UV exposure. Its resistance to thermal shock and chemical reactions makes it ideal for use in quartz beakers, quartz flasks, quartz test tubes, quartz crucibles, and reaction quartz vessels where precision and durability are critical.

Quartz Glassware for Semiconductor Manufacturing/ Semiconductor Quartz Glassware

In the semiconductor industry, quartz glassware plays a vital role in the production of microchips and electronic components. It is used for quartz furnace tubes, quartz crucibles, and other components that must withstand high temperatures and maintain purity during sensitive production processes.

Quartz Glassware In Medical Industry / Medical Industry Quartz Glassware

Quartz glassware is frequently used in medical and pharmaceutical industries for sterilization equipment, drug preparation, and storage containers. Its non-porous nature and resistance to contamination ensure that it maintains the purity and integrity of sensitive substances, such as quartz test tubes, quartz boats, and quartz crucibles. Making it suitable for critical health-related applications.

Quartz Glassware for Optical Application / Optical Quartz Glassware

Why Choose Us As Lab Quartz Glass Products Supplier

Expertise and Experience

With decades of experience in the quartz glass industry, we have the technical expertise to deliver high-quality lab glassware. Our team of professionals ensures that each product meets the strict requirements of laboratory environments, providing reliability and precision.

Custom Solutions

We offer tailored quartz glass products to meet the unique needs of your lab. Whether you need specific dimensions, shapes, or surface treatments, we work closely with you to create custom solutions that align with your scientific requirements.

High-Quality Materials

We use only the highest purity quartz to manufacture our lab glass products. This ensures superior chemical resistance, temperature stability, and transparency, making our quartz glassware ideal for sensitive and demanding laboratory applications.

Global Reach and Fast Delivery

As a global B2B supplier, we offer fast, reliable delivery to laboratories around the world. With efficient logistics and a commitment to customer satisfaction, we ensure timely shipments to keep your lab operations running smoothly.

What Our Other Customers Say About Us

After-Sales Support

-

Technical Assistance:

-

Our dedicated technical support team is available to assist you with any questions or troubleshooting needs after your purchase. Whether it’s product maintenance or application advice, we’re here to provide expert guidance.

-

Efficient Replacement and Return Process:

-

In the event of damaged or faulty products, our hassle-free return and replacement process ensures quick resolutions. We prioritize minimizing any disruption to your operations, offering fast turnaround times on replacements.

-

Customer Feedback and Continuous Improvement:

-

We value your feedback and are committed to improving our products and services based on your input. Our after-sales team actively seeks customer insights to ensure we consistently meet and exceed your expectations.

-

Regular Follow-Ups:

-

We believe in building long-term relationships with our customers, which is why we conduct regular follow-ups after your purchase. Our team ensures that the products meet your needs and are performing optimally, addressing any concerns you may have.

Our Partner

Quartz Glass Products FAQs

What is the purity level of your quartz glass?

We use high-purity quartz with a purity level of over 99.99%, ensuring exceptional performance in both optical and thermal applications. Our stringent quality control processes guarantee minimal impurities, making our products ideal for sensitive environments like laboratories and semiconductor manufacturing.

Can you provide custom sizes and shapes?

Yes, we specialize in custom quartz glass products. Whether you need specific dimensions, unique shapes, or tailored designs, our team works closely with you to create products that meet your exact requirements. We offer a variety of thicknesses, diameters, and surface finishes.

How do you ensure the quality of your quartz glass products?

All our products undergo rigorous quality inspections at multiple stages of the production process. We test for dimensional accuracy, surface quality, purity, and resistance to heat and chemicals, ensuring that each product meets industry standards and customer specifications.

What are your lead times for delivery?

Our typical lead time varies depending on the complexity and volume of the order. Standard products are often shipped within 7-14 days, while custom orders may take slightly longer. We prioritize fast and reliable delivery, offering flexible shipping options to meet your timelines.

Are your products resistant to extreme temperatures and chemicals?

Yes, quartz glass is highly resistant to both high temperatures (over 1000°C) and chemical corrosion. This makes it ideal for industrial processes, laboratory use, and environments where exposure to harsh chemicals or extreme heat is common.

What kind of after-sales support do you offer?

We provide comprehensive after-sales support, including warranties, technical assistance, and an efficient return or replacement process. Our team is available to address any issues or provide guidance, ensuring that our products perform to your expectations.